ERP System for Fleet Management

Introduction: Why ERP-Fleet Integration Matters

If you’re running a business with a fleet of vehicles, whether it’s five vans or two hundred HGVs you’re probably juggling too many systems. One tool for fleet maintenance schedules. Another for payroll. Spreadsheets for fuel tracking. Maybe something else for inventory or dispatch and endless email threads trying to keep everyone updated None of it quite talks to anything else.

At some point, someone (probably you) starts asking the question:

‘Shouldn’t all this be connected?’

That’s where ERP comes in. Or at least, that’s the idea. But integrating fleet management and inventory management into ERP isn’t as simple as plugging in a module. The solutions are varied, the claims are loud, and the reality depends.

This guide exists to make sense of that reality. It’s for business owners, ops managers, and fleet owners who are tired of chasing data across systems and want to know: Is ERP the right move? And if so, how do we do it right?

What is an ERP system and How Does it Relate to Fleet Management software?

ERP (Enterprise Resource Planning) is a messy acronym for a simple idea: systems that work together. Instead of juggling software for accounts, stock, HR and maintenance (each in its own silo) ERP software brings those functions under one roof.

But ERP isn’t just accounting software with ideas above its station. Done properly, it gives businesses a real-time view of what’s happening across the organisation. Orders. Inventory. Assets and people all linked, trackable, and reportable.

So where does fleet management come in? Everywhere. Fleet vehicles aren’t separate from your business. They are your business. They burn fuel (finance), need servicing (ops), carry goods (inventory), and are driven by staff (HR). The stronger the connection between your fleet data and the rest of your systems, the more coherent your operation becomes.

Still, integration is a decision not just a box you tick. What do you want from it? Fewer spreadsheets? Better maintenance scheduling? Real-time vehicle status linked to job costing? Less email communication?

That’s where things start to get interesting.

Share read-only contact lists across 100’s of devices

14 DAY FREE TRIAL

14 DAY FREE TRIAL  NO CREDIT CARD REQUIRED

NO CREDIT CARD REQUIRED

Do ERP Systems Include a Fleet Management module? Understanding the Setup Options

Many business owners start by asking a straightforward question: should we find an ERP system with built-in fleet management, or connect our existing fleet tools to ERP? It’s a fair question and one that reveals how varied ERP setups can be.

There are generally three options

- ERP with a native fleet module

Some ERP platforms offer fleet management as a built-in module. These systems let you manage vehicle data, maintenance, and fuel consumption directly within the ERP environment. The benefit is tight integration with finance, HR, inventory and reporting — but the trade-off is that these modules are often basic compared to standalone fleet tools. - ERP connected to a third-party fleet system

In this setup, a business keeps using its preferred fleet management software, but connects it to the ERP for things like cost tracking, billing or compliance. This gives you more advanced fleet features, but relies heavily on how well the integration is handled. Data flow, syncing schedules and custom development all matter here. - ERP with no fleet component at all

Not all ERP systems are built with fleet management in mind. Some industries never need it. Others solve it entirely outside the ERP stack. In these cases, businesses either accept the separation, or build a custom bridge between systems to avoid double-handling data.

Understanding which model fits your needs — and your existing software landscape — is key before you start evaluating platforms. The term ‘integration’ gets thrown around a lot, but what it means in practice varies more than most people expect.

Which Setup Is Right for You? Matching ERP-Fleet Models to Real Needs

It’s one thing to understand the options. Choosing the right one is harder. Many of the frustrations people share (on forums, in boardrooms, over spreadsheets) come down to trying to force a setup that doesn’t suit the way their business actually runs.

So how do you figure out what fits?

Start with what you already have. Are you using a fleet management system that works well? Or is that the weak link? The answer will tell you whether ERP should take the lead or follow the fleet.

Then look at depth. Do you need advanced features — real-time GPS, maintenance tracking, driver performance data? Or are you really after better reporting and tighter links between ops and finance? If it’s the former, a standalone fleet platform might stay. If it’s the latter, ERP might be ready to take more control.

Think about the people, too. Do you have technical staff who can support integration work? Or will every system link need a contractor and a prayer?

And timing. Is ERP already in place? Are you just now considering it? Are you midway through trying to get two platforms to talk to each other?

There’s no single right answer. But asking the right questions at this stage will save months of frustration later.

Is ERP the Right Fit for Your Fleet? Key Considerations

ERP systems promise clarity. But before you commit to one, you need clarity of your own. Not every business is ready for ERP, and not every ERP is ready for your business.

Start with scale. If you’re running a five-vehicle operation with modest growth plans, a full ERP rollout might be overkill. You’ll be paying enterprise-level costs for implementation, licenses and ongoing support, without seeing enterprise-level returns. Some industry voices suggest that unless your business is approaching £10 million in annual revenue, the overhead of ERP may outweigh the return.

Then there’s the time cost. A proper ERP implementation isn’t a quick install. You’re looking at three to six months. It takes planning, process-mapping, testing, and training. If you’re already stretched thin, be honest about whether your team has the capacity to handle that kind of change.

Integration is another pressure point. Most businesses already have something in place: accounting software, a vehicle tracker, a stock system. Replacing everything at once rarely works. But stitching ERP into your existing tools can create its own mess. Custom development, data migration, inconsistent reporting — these are all solvable problems, but they take time, money, and the right people.

And then there’s usability. One of the most common pain points is getting staff to use the system properly. Not because they’re resistant, but because it’s not intuitive. Training is rarely just a one-off. It’s an ongoing cost, both in time and in confidence.

So, before you dive in, ask yourself:

- What am I trying to fix?

- What does success look like?

- Can my team absorb the disruption?

- Can I justify the cost, not just upfront, but long term?

ERP can be transformative but it isn’t plug and play. It’s a commitment and it only makes sense if you know what you’re committing to.

What You Stand to Gain: The Real Benefits of ERP-Fleet Integration

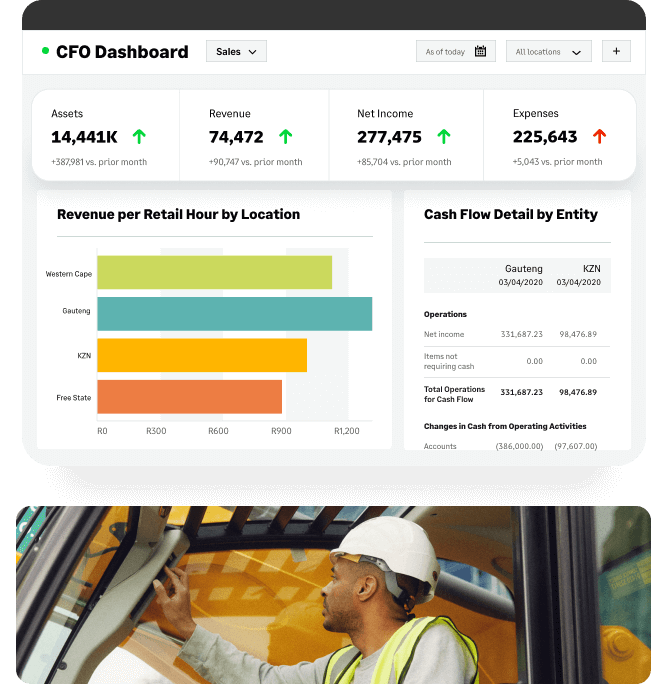

If ERP is done right it can change how a business operates. Not just how it manages vehicles, but how it sees itself. For fleet-heavy organisations, integration can offer a kind of clarity that’s difficult to get any other way.

1. Joined-up operations

Fleet doesn’t sit in a corner. It connects to finance, HR, customer service, compliance, and more. A delivery logged by a driver can instantly update stock levels, trigger a purchase order, and notify accounts. It removes the gaps.

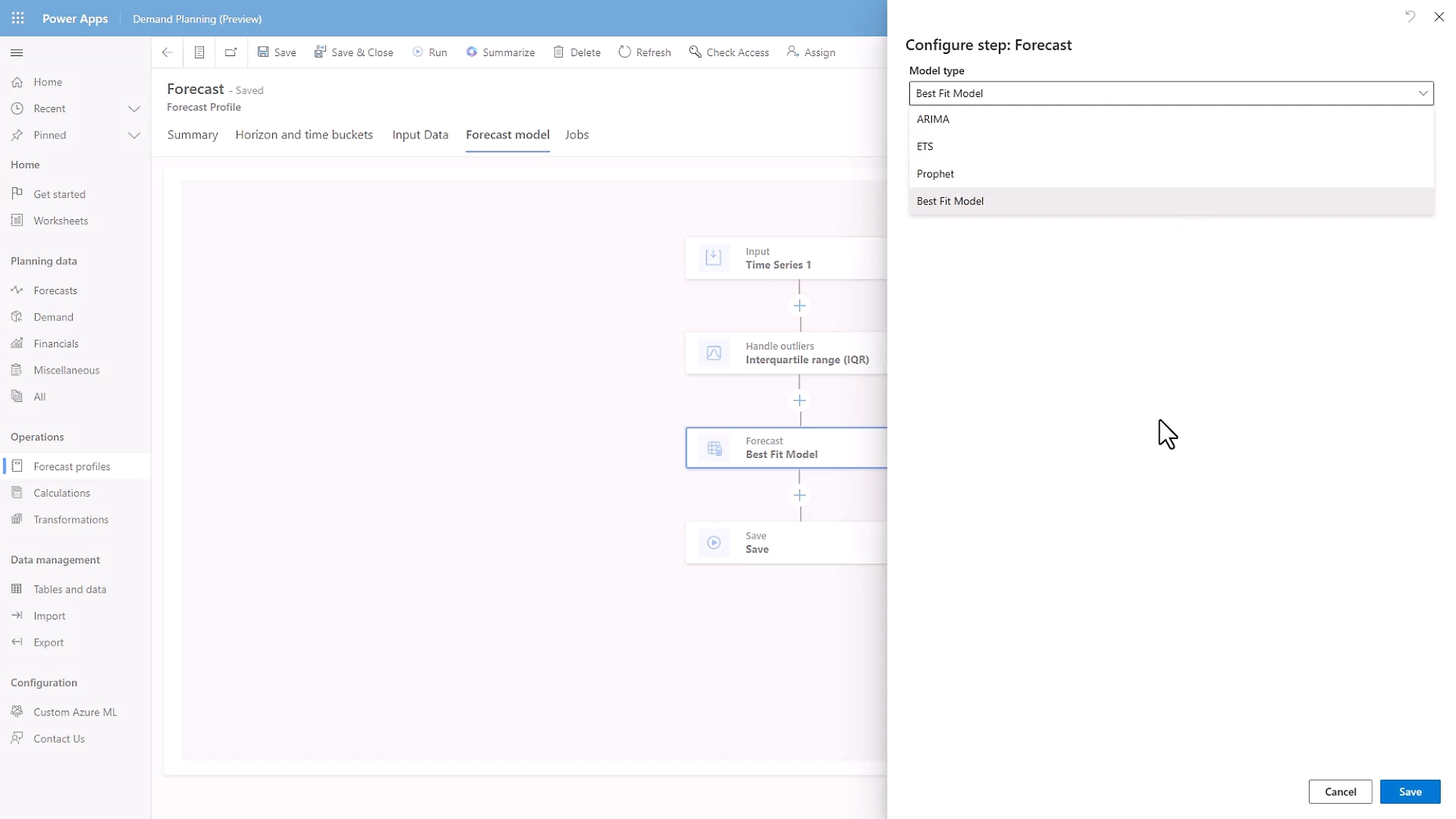

2. Fewer surprises, better planning

When servicing data is tied to inventory and job costing, you’re not guessing when a van will be off the road or how much it’ll cost. Fuel spend, driver hours, location history — all visible, all in one place. Forecasting becomes something you can trust.

3. Less admin, more visibility

ERP replaces rekeying with real flow. Data moves once, cleanly, and updates where it needs to. No need for multiple systems to be manually reconciled at the end of each month. This saves time and improves accuracy.

4. Stronger compliance and traceability

For fleets in regulated industries, record-keeping isn’t optional. An integrated system gives you auditable logs of who did what, when, and with what outcome. From maintenance schedules to driver certifications.

5. A foundation that can scale

As fleets grow, so does the complexity of keeping them running. The advantage of ERP as well as centralizing is that your systems grow with you, without needing to be reinvented every time the business expands or changes shape.

What to Expect: Core Fleet Features to Look For

Before deciding how ERP and fleet management will come together in your business, it helps to know what features are actually out there. Whether these live inside ERP, in a standalone fleet system, or across both, these are the capabilities that tend to matter most.

Feature | Why it matters | Where it typically lives | Good to know |

|---|---|---|---|

Vehicle tracking & GPS | Real-time visibility, route optimization, safety | Usually in dedicated fleet tools. Sometimes in ERP, with limited detail | Check update frequency and integration with dispatch or maps |

Driver management | Tracks hours, compliance, licences, incidents | Often split between HR in ERP and the fleet system | Watch for duplicate records or gaps in oversight |

Maintenance scheduling | Reduces breakdowns, manages costs, plans downtime | ERP asset module or fleet system | Best when linked to parts inventory or supplier data |

Fuel tracking | Controls spend, detects anomalies, supports carbon reporting | Typically handled in fleet systems or via fuel card integrations | May be manual or automated — accuracy varies |

Route planning & trip logs | Improves efficiency, reduces delays and idle time | Usually in specialist fleet software | Relevance depends on how logistics-heavy your operation is |

ERP-Fleet Solutions by Business Size

Not every business needs full ERP. And not every fleet needs full integration. What’s appropriate depends heavily on your size — not just number of vehicles, but people, processes, and capacity to manage change.

Small Businesses

Under 50 vehicles / under £5 million turnover

At this level, the priority is usually reducing manual admin without introducing unnecessary complexity. Most small fleets are already using a mix of spreadsheets, accounting tools, and perhaps a basic fleet app. Jumping straight to enterprise ERP is often a step too far.

If you’re just trying to get systems talking to each other, a lightweight or open-source ERP might be enough. These options are often free or low-cost, with community support and modular add-ons that let you join up data without drowning in overhead.

Tools worth exploring:

- ERPNext – Excellent for small fleets, especially with the Frappe-based fleet management system. It offers real-time tracking, telematics, automated expense management, maintenance scheduling, and integrates accounting, HR, and procurement. Its open-source model and active community make it scalable and customizable for small businesses.

- Odoo (Community edition) – Suitable for small and medium-sized enterprises with basic fleet needs. The Community edition includes essential fleet management features—vehicle records, maintenance, contracts, and fuel management. The Enterprise edition adds more automation and mobile support, but for small businesses, the Community version is often sufficient and cost-effective.

- Zoho One – not traditional ERP, but includes enough tools to unify small business operations affordably.

Mid-Size Operations

50–200 vehicles / £5–50 million turnover

This is often the tipping point. Separate systems for fleet, finance, and operations start to drag on efficiency. Missed maintenance, mismatched inventory, and duplicated admin become cost factors, not just annoyances.

At this stage, most businesses either bring in a formal ERP or strengthen the links between systems they already use. The priority shifts to integration and data flow. It’s less about finding “one tool to do it all” and more about ensuring the right tools work together.

Platforms commonly used:

- Microsoft Dynamics 365 – Microsoft Dynamics 365 Business Central, paired with a dedicated Fleet Management app, brings all your fleet, finance, and operations data into one platform. Track vehicles, drivers, maintenance, and expenses with advanced reporting.

- Sage Intacct – Sage Intacct is a leading financial-first ERP, widely used in transportation and logistics. While it doesn’t natively include fleet modules, it is designed for seamless integration with specialist fleet management or TMS platforms.

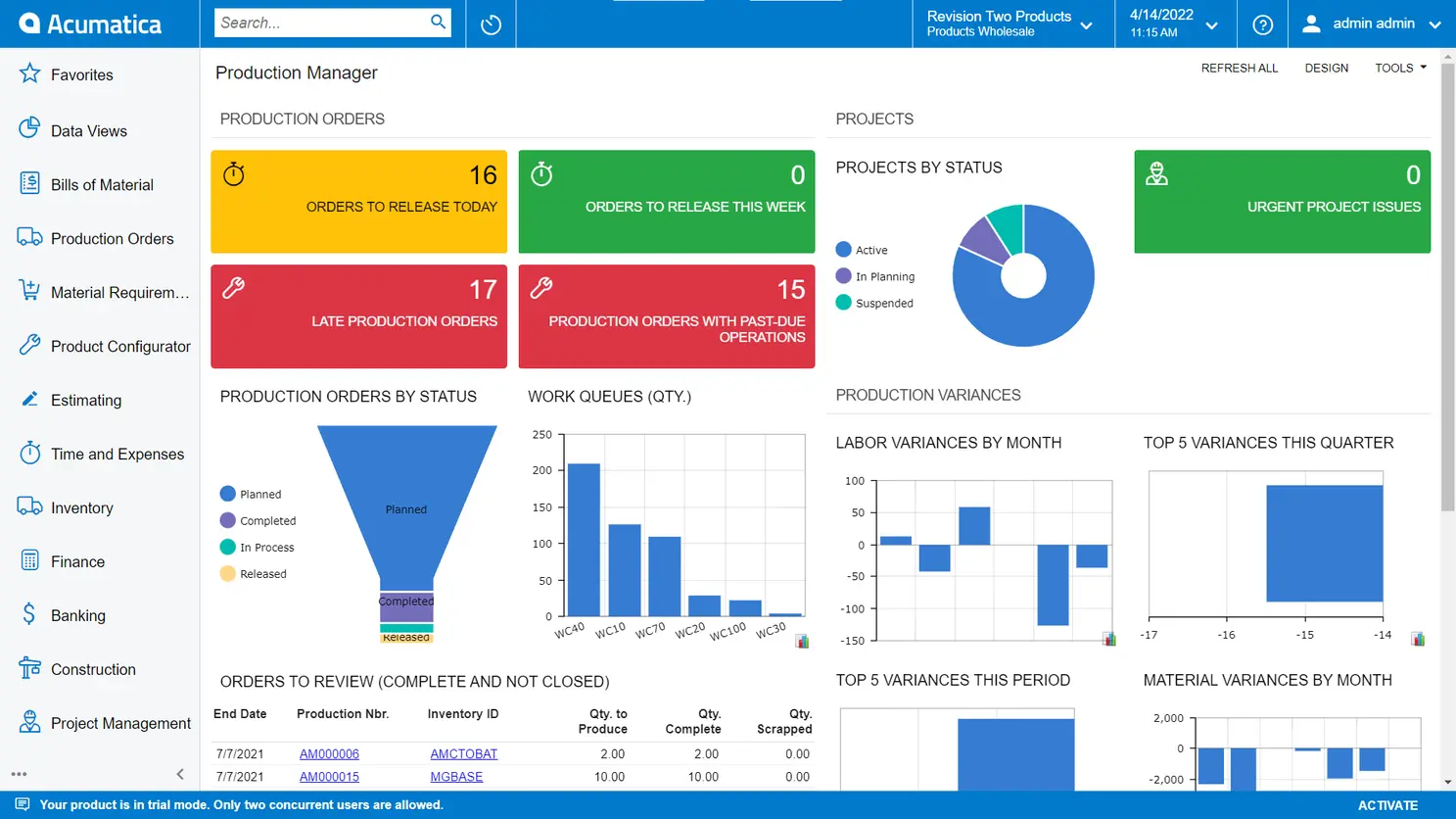

- Acumatica – Acumatica Cloud ERP offers a future-proof, scalable platform with flexible APIs—ideal for integrating fleet management, finance, and operations. Its asset management and customizable workflows help mid-size fleets streamline processes and adapt as they grow.

Large and Complex Fleets

200+ vehicles / £50 million+ turnover

At this level, disconnected systems simply don’t scale. You’re likely dealing with multiple teams, entities, regions, or compliance environments. ERP becomes the operational backbone, and the focus turns to how well it can integrate with specialist tools — or whether it already includes the modules you need.

Enterprise-grade platforms offer power and depth, but come with long implementation times and steep licensing models. The benefit is control: clearer reporting, streamlined compliance, and less reliance on patchwork solutions.

Enterprise options in this space:

- SAP S/4HANA + Accão Fleet Module – SAP’s core ERP connects with the Accão Fleet Management add-on for integrated vehicle tracking, cost control, and maintenance—all directly inside the ERP environment

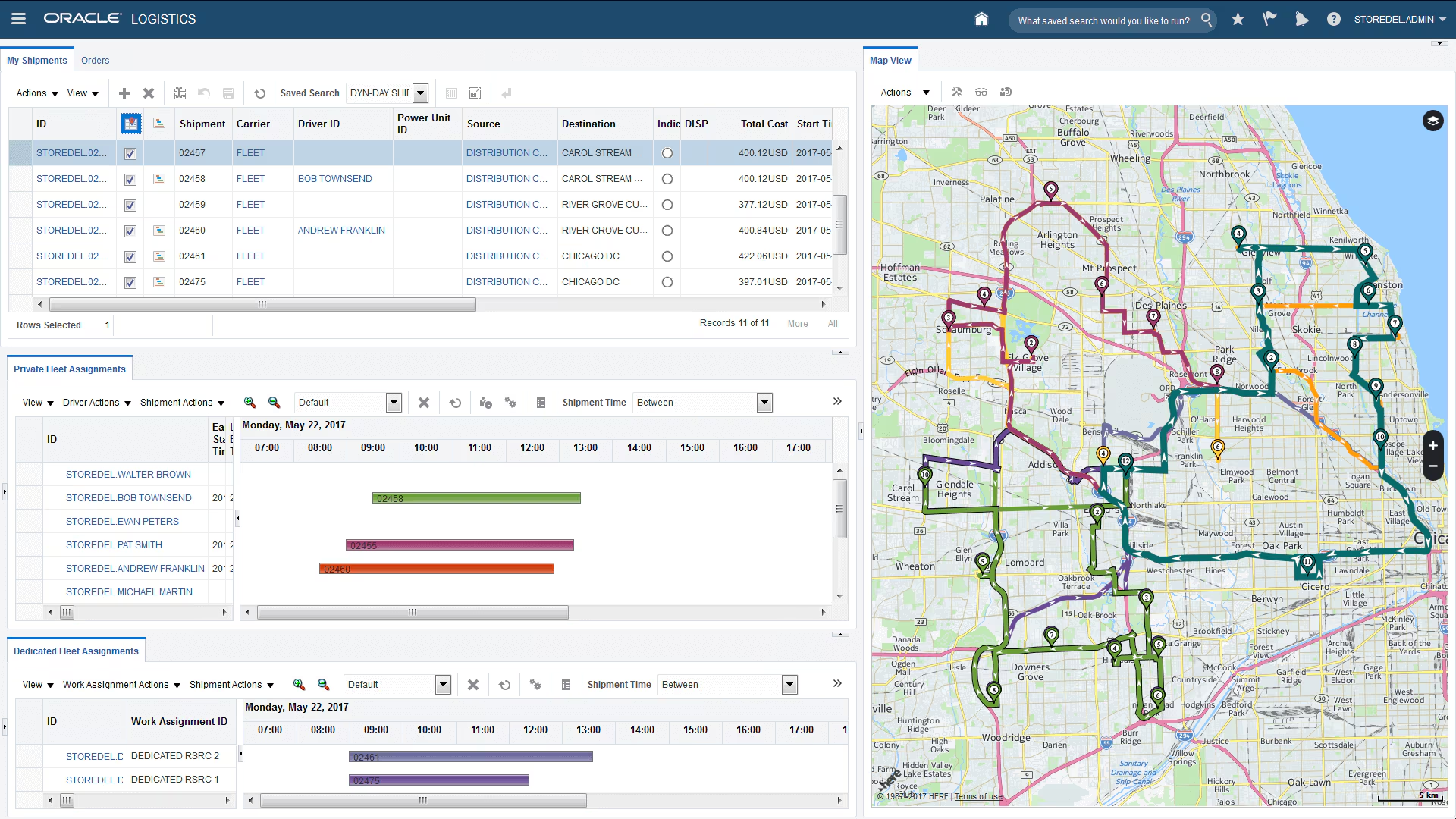

- Oracle Cloud ERP + Fleet Integration – Oracle’s global, cloud-native ERP suite supports asset-heavy operations with robust modules and third-party fleet integrations—delivering deep financial and operational oversight

- Onyx ERP – Fleet Management Solutions – Onyx ERP offers dedicated fleet modules for vehicle tracking, leasing, maintenance, parts, and driver records—ideal for large carriers and asset-intensive fleets

Industry-Specific Priorities: When Your Fleet Isn’t Like Everyone Else’s

Not every fleet runs the same way. The priorities of a logistics company are very different from those of a service business, or a manufacturer with field operations. When you’re looking at ERP integration, the industry context matters a lot.

Transportation and logistics

Speed, routing, fuel cost, and uptime are everything. You’ll need deep integration between vehicle tracking, delivery schedules, and warehouse inventory. Look for systems that support real-time dispatch, dynamic routing, and maintenance forecasting.

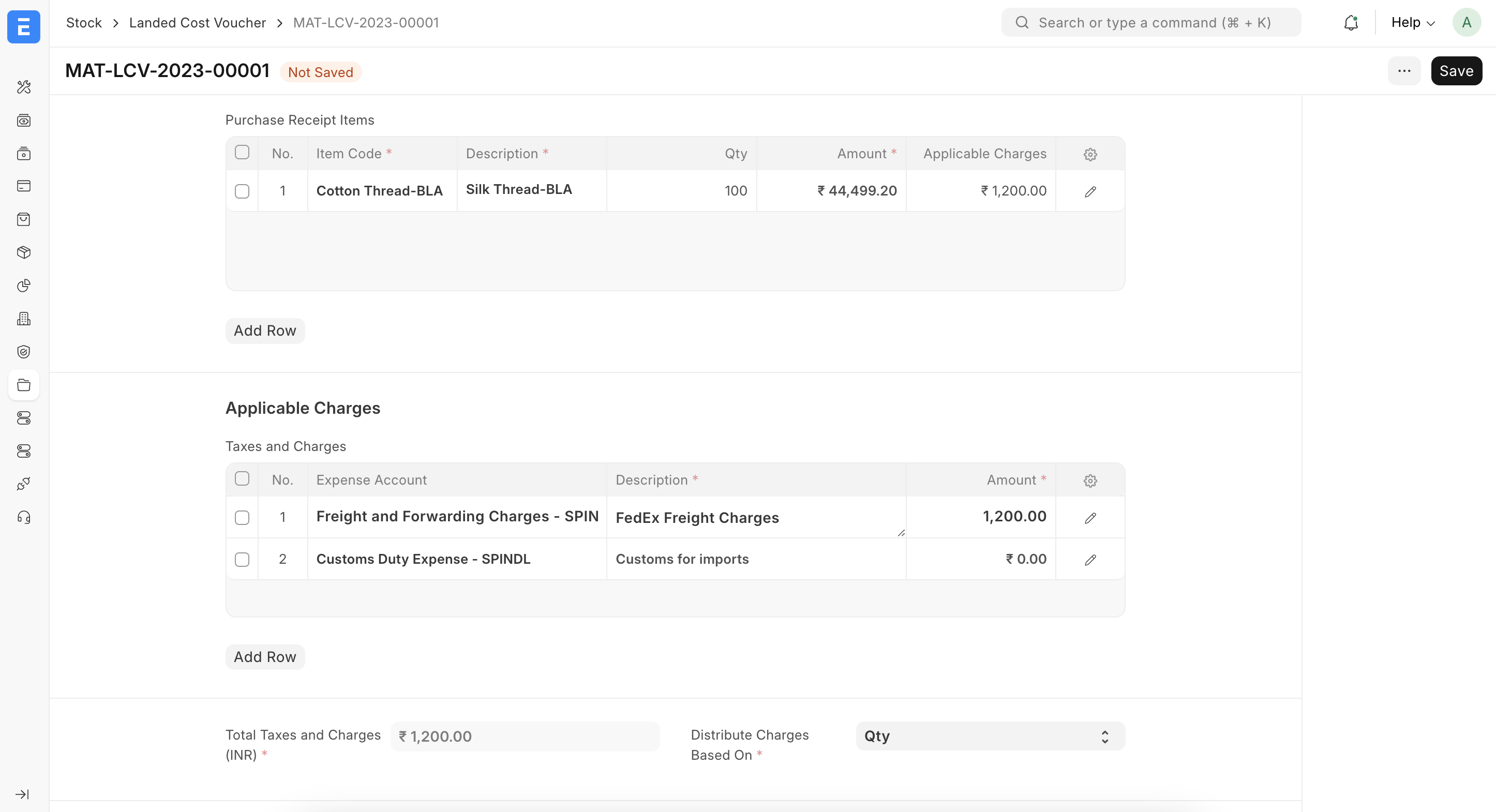

Manufacturing with distribution

Here, vehicles are just one part of a tightly linked supply chain. The focus is on syncing fleet data with production timelines and inventory turnover. Integration with warehouse management and procurement is key.

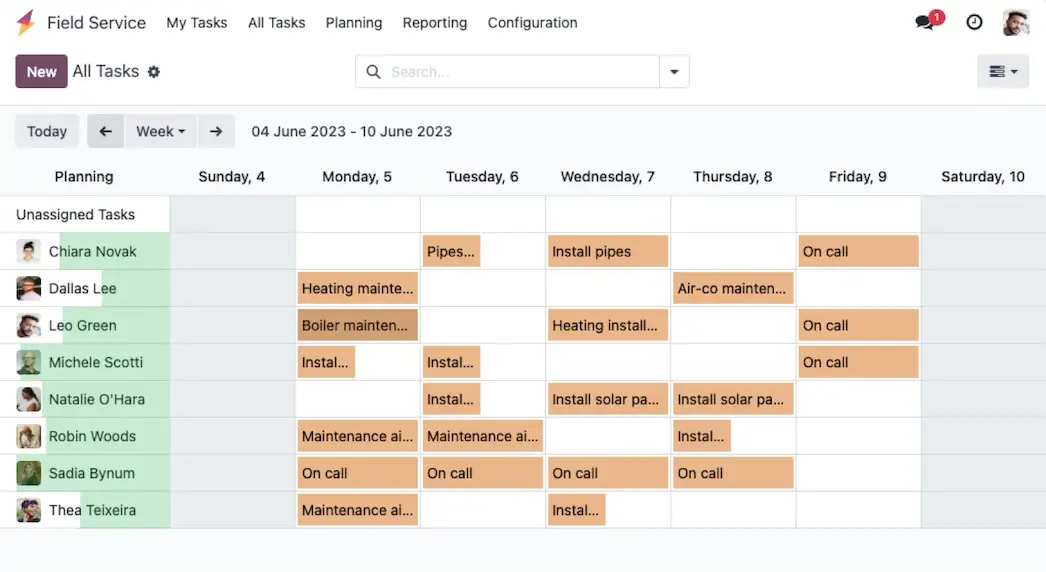

Service businesses with field operations

For companies sending engineers, installers or technicians into the field, job scheduling and real-time location tracking matter more than routing efficiency. ERP needs to sync with CRM, mobile work orders, and stock held in vehicles.

Chemical or specialised product carriers

Compliance, traceability, and safety take priority. You may need integration with regulatory reporting tools, hazardous goods tracking, and condition-based monitoring for vehicles. Off-the-shelf setups may not go far enough here.

Making It Pay Off: What ROI Looks Like in Practice

Investing in ERP is rarely about short-term gain. It’s a decision that affects how your business runs, how people work, and how information moves. So when people ask whether integrating fleet management with ERP is worth it, what they’re really asking is:

‘when do the benefits justify the cost, effort, and disruption?’

Where savings typically come from

- Time

Less manual entry, fewer reconciliations, and quicker access to usable data. - Visibility

Better insight into operations. From fuel usage to driver hours, everything is in one place — not scattered across tools. - Uptime

Good maintenance tracking can prevent breakdowns and reduce unexpected downtime. - Compliance

Integrated systems support audit trails, safety checks, and documentation. Especially valuable in regulated sectors.

What to consider

Smaller businesses

ROI may come from eliminating workarounds. Time saved on admin. Fewer mistakes. Less time spent fixing things that should run smoothly.

Mid-size companies

It’s often about operational efficiency. Avoiding duplication. Automating what used to be manual. Linking spend to activity and tightening up decision-making.

Enterprise Scale

ROI means system-wide control. Consistency, oversight, and data that supports growth without constantly adding more people.

Payback periods vary. But when ERP is aligned to what the business actually needs, and rolled out with care, the return is lasting. It’s not just financial. There will be added clarity, structure, and control.

Frequently Asked Questions

What ERP platforms work with complex fleets?

How does ERP enhance fleet management operations?

ERP connects scheduling, asset tracking, maintenance, inventory, finance, and compliance in one system. That centralization reduces manual data handoffs, strengthens visibility across field teams and vehicles, and ensures real-time decision-making—streamlining operations from planning to reporting.

How does ERP improve job scheduling and real-time tracking?

ERP links CRM, mobile work orders, and vehicle tracking into a unified view. That integration ensures jobs are scheduled based on capacity and location, monitors live vehicle status, and updates work order progress instantly—minimizing delays and manual coordination.

Can ERP help with compliance for hazardous goods carriers?

Yes. ERP can track hazardous materials across transport, maintain audit trails, manage regulatory documentation, and integrate with reporting tools. That ensures traceability, supports safety protocols, and keeps you compliant with industry regulations and inspections.

What is the typical ROI payback period for fleet ERP?

Most fleets recoup ERP investment within 12 to 24 months. Savings come from reduced manual admin, fewer errors, lower downtime, and efficient maintenance. Mid-size to enterprise fleets often see measurable returns after the first year of streamlined operations.

How can ERP reduce vehicle downtime and maintenance costs?

ERP automates maintenance schedules, logs repairs, and monitors vehicle health. Predictive alerts flag potential issues before failure. That proactive maintenance prevents breakdowns, lowers emergency repairs, and increases overall asset availability.

What ERP platforms work with complex fleets?

Platform examples suited for complex fleets include Enrich ERP, 3GL ERP, and ArionERP. These systems support multi-modal assets, compliance tracking, telematics integration, parts inventory, and finance modules—ideal for specialised carriers, leasing fleets, or hazardous goods transport